Farm Safety Basics and How to Manage Safety in Agriculture

New to farm safety and not sure where to start? We've got a guide made just for you.

Introduction

You’ve heard you need to do something about safety – but what exactly?

Setting up a safety management system is the smart thing to do. The good news is doing this is relatively simple if you follow a few basics.

Yes, you’ll need to invest a bit of time initially to set up the basics of your system but it’s time well spent to keep safe and keep farming.

Narrowing down your options of farm safety management systems can be an overwhelming task. You have two clear options; a safety management systems that claim to cater to everyone and industry specific systems that are made exclusive for agriculture.

Here's what you can expect to learn in this article:

Chapter Contents

01 What is a Safety Management System in Farming?

A Safety Management System, also referred to as an SMS, is a systematic approach to managing safety. Your Safety Management System should assist with managing health and safety duties and responsibilities. A good system supports your farming business operations on a daily basis with decision-making insights.

What is the purpose of a safety management system? Whilst a safety management system involves documentation, that isn’t all it is. Its focus is on effectively protecting your workers from harm, preventing injury or illness and achieving your safety goals. It should document your policies, safe work procedures, emergency procedures, record keeping supporting compliance and more.

A well designed and implemented safety system should help improve productivity on your farm by giving your workers the right information at the right time, and reduce downtime by addressing hazards and preventing safety incidents.

It also provides a level of protection from potential penalties and prosecution if something serious does happen.

02How to develop a Safety Management System

You will probably have some elements of a safety management system already in place, but there are four elements to keep in mind when developing your system: plan, support, perform, improve.

Planning entails your documentation; your policies, procedures, checklists, reporting, emergency response plans - the documents that communicate your expectations and commitment to a safer workplace.

Support includes your risk management process. What tools will you implement as part of your Safety Management System? Think about how your team will identify hazards; safety inspections, near miss and incident reports, hazard mapping and risk assessments. Then develop how you will monitor and control the risk - can you eliminate, or substitute the hazard for something less harmful?

Performance, sometimes called safety assurance, involves reviewing the previous action - Did the risk controls work as you thought? Could they be improved further or has it created a new risk? This evaluation process will include consultation with your workers as well as internal audits and reviewing your risk register.

Your Safety Management System will be constantly changing and developing over time. You will implement improvements through learnings and your review process. This last element is linked to your safety culture - training, education, communication, awareness and leadership. Don’t forget to celebrate the wins and report on positive actions that have improved safety on your farm.

03Create Health and Safety Policies

State your commitment to keeping yourself and others safe.

When you have an idea of what you expect from your workers and others, start by creating a Work Health and Safety Policy. This is an overarching policy which tells everyone what farm safety on your property is all about. There are plenty of templates you can use, just make sure you adapt it to suit you and your business.

Download a FREE Work Health and Safety Policy

Along with the overarching policy, think about other things in your business where you need to provide some guidance to your workers and others.

This could include what to do in the event of an emergency, what your position is on use of drugs and alcohol at work, and safe use of chemicals and machinery. These are just a few common examples for agriculture. Develop policies around these also and make sure you share all of these with your workers.

Safe Ag Systems most popular templates

-

Work Health and Safety Policy

-

Operating Machinery and Equipment Policy

-

Chemical and Chemical Spill Incident Policy

-

Contractor on Farm Policy

-

Fit for Work Policy

Your policies should hold people accountable and make sure everyone does their part. Promote health and safety as a high priority, get involved with farm safety initiatives and lead by example.

Get access to them all, start your FREE 7-Day Trial now!

04Managing Risk

Hazard. Risk. Same thing - right?

In short, no. While the terminology isn’t important, understanding the difference is.

A hazard is something with the potential to cause harm. Risk is the likelihood or chance of it happening. Eg, barbed wire is a hazard. On its own it poses no risk to you. But you throw your leg over a barbed wire fence and there’s sure to be a risk of getting caught.

There are many hazards in agriculture, including:

-

machinery

-

chemicals

-

livestock

-

confined spaces

-

water and so on.

Find out what the most common hazards are in your commodity.

The trick here is to think about your business and commodity, then consider what could hurt or kill someone (the risks) and start from there.

You need to do everything ‘reasonably practicable’ to manage risks. If you can’t reasonably manage the risk, perhaps you shouldn’t do that thing.

When it comes to managing hazards and risks, your obligation as a PCBU, responsible person and/or an Officer is to eliminate them, or if you can’t eliminate then you need to effectively manage them. A risk assessment is a step closer to ensuring you are protecting your workers, family, and anyone else on farm as far as reasonably practicable.

Having documented processes is a great foundation to your system and often where most people start. Just make sure your processes are followed in day-to-day operations.

Where an unforeseeable hazard result in a health and safety risk or worse, the result is an injury to a worker, you need to have near miss and incident reporting in place. These reports allow managers, supervisors and PCBUs to review or investigate whilst implementing improvement actions to help prevent the issue from reoccurring.

If the potential was there for an injury to occur, then these incidents or near misses must be reported. Some examples of such incidents could include large, heavy items falling from a truck during loading or unloading or a significant chemical spill. Did you know you are legally required to keep a record of each notifiable incident for at least 5 years?

05Consultation

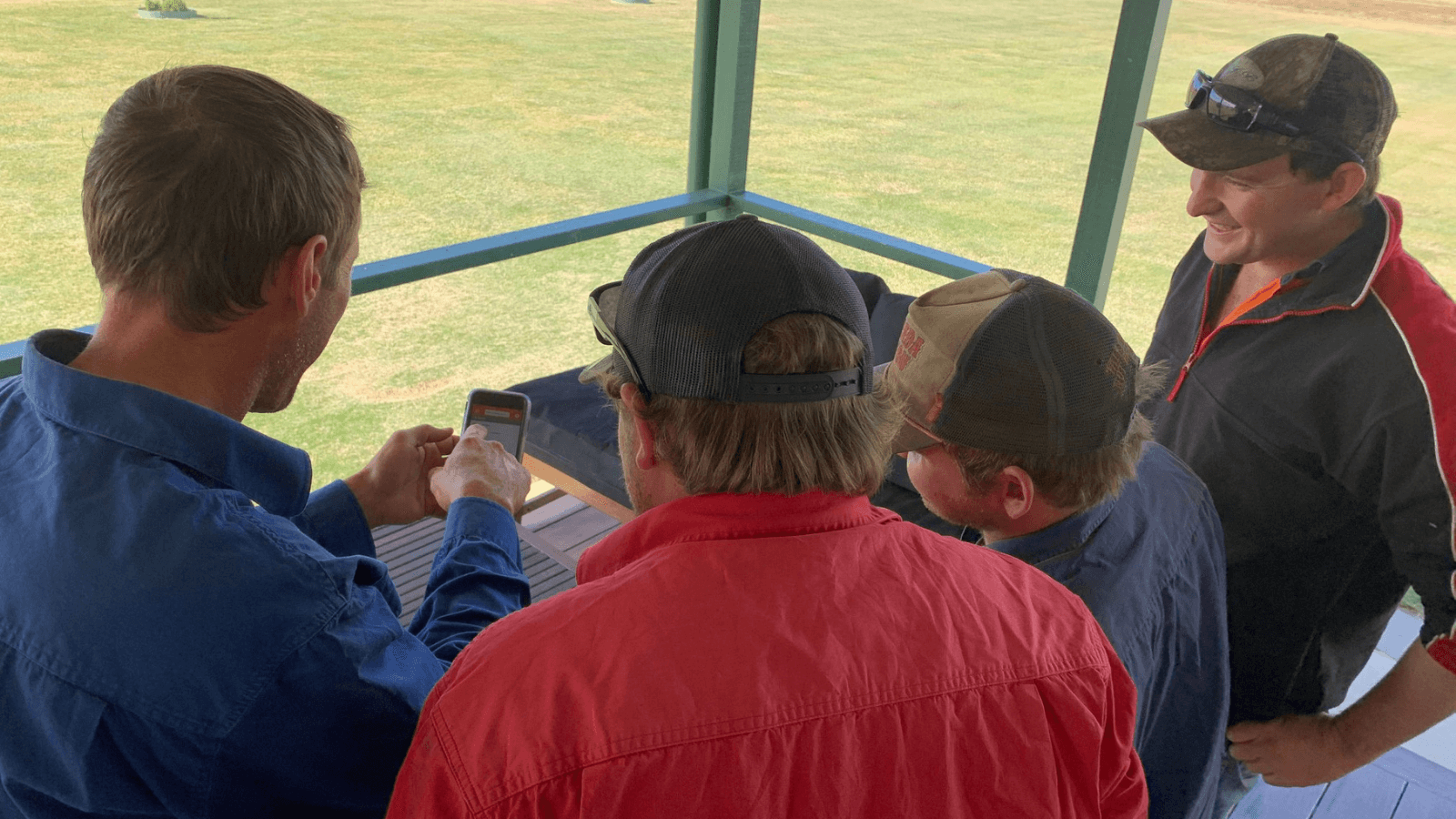

The duty to consult with workers and others around safety is enshrined in legislation, so it’s a ‘must do’ from that perspective. But there’s good business reason for it too.

Consultation is a two-way conversation where you talk with, and listen to your workers.

Talk to them about what you’re thinking in regard to farm safety, and give them an opportunity to give feedback. Often, you’ll pick up some great ideas from workers which could save you time and money.

Worker consultation does not require consensus. It’s not a ‘vote’ situation. You can still make a decision, but you do need to consider what’s been put forward through the consultation process.

There’s also a requirement to consult with others. This might be a contractor coming in to do some work for you, or a transport company collecting your commodity. Where there’s a common duty for safety you need to have that two-way discussion so you’re all on the same page.

06Information, Training and Supervision

With your system now documented and ready to go, make sure your workers and others know what they need to do.

- Information. Start with new workers and contractors being inducted. Induction sets the basis for their safety when working for you.

- Training. From there, you need to continue to train people on your policies, safe work procedures, operations and machinery. By doing this your workers should be able to demonstrate they can safely perform tasks.

- Supervise workers. You don’t need to be watching over their shoulders at all times but you do need to make sure they are doing the work you need them to do, and doing it safely. Be available if they have any queries and encourage them to come to you.

Make sure you also induct contractors and visitors. These inductions may differ to that of your workers, but induction is important. Let them know about hazards on your property they may come across. Just because you know it’s a hazard, it doesn’t mean they know.

Employers have a legal obligation to ensure the safety of everyone on their farm and are responsible for ensuring everyone is briefed on your emergency procedure.

07Implementing your Safety Management System

You've set up a good safety management system. Now be sure to implement it.

If you’ve invested time and possibly money in to developing it, use it across your business. By setting a good safety culture you should see increased productivity, increased worker satisfaction and reduced downtime.

Did you know?

Agriculture accounts for 3% of the Australian workforce.

In 2017/18 there were 3560 serious claims (one week or more of lost time).

Average cost per claim = $11,100.

Average time lost per claim = 5.7 weeks.

Total industry cost = $40.5m, 20,292 weeks of lost time.

PLUS 37 FATALITIES

Note: 2017/18 of preliminary data subject to revision as further claims are finalised.

In the UK the total industry costs were estimated at £190 million, two thirds are attributed to reportable injuries with fatalities labelled as the remaining third*.

Follow up and check how things are going.

It’s your safety management system so you can update and improve things as you need to. Hazards change, risks change, so your system needs to take this in to account and move with the changes. Now is the time to start measuring and communicating the positive impacts that your safety program is generating.

Set aside some time at least once a year to focus on how safety is working for your business. A tool to help you prevent risks, a safety inspection is generally a walk through performed on-site. As part of your hazard identification tool kit, the purpose of a safety inspection is to provide you with the ability to identify, and report on, potential hazards and dangers in your workplace that can be removed or avoided.

One of the simplest safety management tools, an agricultural safety checklist encourages best practice, and while they might be viewed as tedious and repetitive, they can remind us to not cut corners. Often safety checklists are used as part of your inspection process, they assist in identifying potential hazards and making recommendations specific to your farm.

Did you know an operational software like Safe Ag Systems can help you manage your assets, workers, contractors, regulatory compliance and of course farm safety!

Consider your operations and compare how things are going now compared to a year ago. Keep notes of what’s improved, what’s new, what’s not working so well. Then plan what you want to improve in the coming year. This forms part of the continuous improvement loop.

08Keeping Records

When you've got everything in place, keep records.

Without this evidence, you may leave yourself vulnerable in the event of a workplace incident. Good WHS record keeping is a fundamental of good business. Keeping safety records is part of that. Find out why its important to keep your records current.

Encourage your workers to proactively report incidents and hazards, and ensure you act to address these.

“The more you know about what’s happening in your business, the more chance you have of preventing a serious incident”.

After a serious incident, or if the worse should happen, an regulatory inspector will want to determine how something has occurred. If this has involved machinery or equipment, they will want to see your maintenance records.

Keep records of training including inductions, worker health records, any safety meetings, notes of any consultation and copies of licences or tickets for operating certain equipment. A diary note will be better than nothing for evidence of meetings, consultation etc. Or try a digital safety system to make life easier.

If you are ever involved in a health and safety investigation you will need to provide your safety documentation. Records don’t need to be War and Peace, but they do need to be enough to show what occurred. Checklists and sign-in sheets are an easy way to keep records. Inductions, training, consultation.

In Summary

Managing farm safety is an ongoing process.

- Plan how you will manage safety

- Implement that plan and,

- Regularly check to make sure it’s working.

Things don’t always go to plan, a bit like farming. And that’s OK. Be ready to come up with Plan B and get rolling with that as needed. You already do this on a daily basis in your operations, and safety is just part of that.

You might also like

How to smoothly transition to safety management software

Learn More

Can you actually put a ROI figure on investing in safety?

Learn More

How can a safety system change safety culture?

Learn MoreNever miss out

We’ll send you our latest blog articles, important ag news and free resources!

Resources

Our Company

Copyright 2025. Safe Ag Systems

- Privacy Policy

- Terms and Conditions

- Data Protection & Security